Specialists in Solid Concrete Foundations

262-886-2258 • perma@permastructo.com

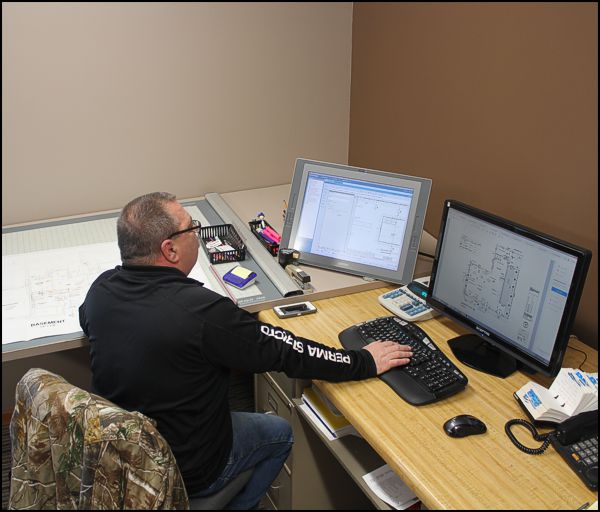

Bidding Your Job

Send prints to bids@permastructo.com or drop a full set off at our office to be bid. We will carefully review your plans and get a proposal out to you in a timely manner.

Scheduling Your Job

After you have chosen Perma-Structo as your concrete contractor, you will need to sign and return the proposals. You may send your signed proposals, current print, survey and permit to bids@permastructo.com or drop them off at our office. We will then contact you and / or your excavator to schedule your footings.

Inspections

After scheduling your job, our office handles the rest. We call in all of our inspections and recertifications for the footings and walls. This provides a hassle-free process for you or the expeditor. For those counties that require you or the builder to call for backfill inspections, we will contact them and let the right person know the process is ready.

Footings

We are using the latest high-tech layout instrument to ensure your footing is properly placed after excavation. The footing is then formed with Form-A-Drain, a top of the line, permanently installed system that forms footings, drains foundations and provides a sub-slab perimeter radon evacuation system all-in-one.

Form-A-Drain

To find out more information about Form-A-Drain, check out this brochure and learn all the great benefits

Footings Pour

Once formed, the stone to protect the drainage system and underfloor stone base are placed using our 110 ft. conveyor. This truck allows us to keep our jobs on schedule. After the local building inspector inspects the job, we pour the concrete for your footing. The next day, the footings are stripped and the job is prepared for the wall crew.

Set & Pour Walls

Typically, a foundation wall can be formed and poured in one day. We are capable of forming many difficult angles, radius and wall heights. The forms and equipment are placed onto the job using one of our boom trucks. Ninety-nine percent of our walls are poured using a concrete pump, allowing the crew to place a mixture of concrete that is stiffer, increasing the strength.

Brick Design

Brick Design is available in full 8' and 9' forms. The brick design pattern gives a unique, uniform look to resemble bricks throughout the inside of the basement walls. Smooth basement walls are also offered. A concrete contractor that properly maintains the forms will provide the finest quality.

Concrete Mix

With over 50 years of experience, we have developed the perfect concrete mix for all different seasons and weather related conditions. It is important to use a concrete contractor that has extensive knowledge and a great relationship with their supplier. This will provide you with the best product.

Rebar

Currently, the Wisconsin Uniform Dwelling Code does NOT require any steel rebar reinforcement be placed throughout a typical wall. Steel reinforcements add strength to the wall and help reduce shrinkage cracks. Our standard 8' wall has 2 #4 bars placed horizontally and the 9' wall has 3 #5 bars placed horizontally. Extra steel is added at the haunch arms and windows. We take extra steps to make sure your concrete walls will stand a lifetime.

Windows

All of our windows are poured-in-place systems. We offer a variety of different window sizes to adjust to your design needs; if otherwise, treated openings are available.

Foundation Anchor Bolts

Anchor Bolts are placed throughout the house and garage walls per code.

Stripping the Walls & Restone

After your wall is poured, we will remove or "strip" the forms. This will usually take place the next day, but it is dependent on weather conditions (i.e. rain, snow, extreme cold temperatures or wind). Once the forms are removed, a series of control joints are cut into the walls. The control joints help control the cracking that is typical in all types of concrete. The joints are then sealed with a waterproof mastic. Most jobs require some type of exterior insulation which would be applied at this time. After insulation is applied, the conveyor will return to the job and place a layer of stone over the exterior Form-A-Drain per Wisconsin code. The job is now ready for a back-fill inspection.

Control Joints

We place strategic control joints through-out the walls to help control where shrinkage cracking occurs. Shrinkage cracking is a common result due to the evaporation of water which is used to make concrete. Waterstop mastic is placed over the control joints on the outside to prevent water or other particles from getting in the control joints.

Foundation Wall Bracing

Depending on the length of the wall, foundation bracing should be used before backfill. We provide proper foundation bracing when it is required.

Backfill

Before backfill, a minimum of 12" of stone is placed around the exterior of the foundation to help with drainage. This is required per the Wisconsin Uniform Dwelling Code.All egress wells offered are filled with 1" stone to the bottom of the well.

Flatwork

Flatwork takes place after the framing of the home has been completed, shingles are on and your underground plumbing has been inspected. Typically, we will send a crew to set up the job and call in a basement floor inspection. This is a code requirement before the basement floor can be poured. After the inspection passes, our crew will usually be able to pour and finish the job in one day. The following day, a crew will come out to saw-cut joints and cleanup the job. Note: It is very important to have power or access to power to keep your sump pump working at all times. Failure to do this can increase hydrostatic pressure under your slab, which can lead to damage.

Concrete Mix

With over 50 years of experience, we have developed the perfect concrete mix for all different seasons and weather related conditions. Our mix is specially designed to withstand the freeze-thaw cycles that will occur in our region.

Control Joints

Joints are cut by our quality standards or by the project specifications. A sufficient number of control joints are installed.

Finish

All stoops our broom finished. Basement and garage floors are hand finished smooth. Rainlips are a standard at all overhead garage doors. Safety grooves are edged in for all garage steps.